Gadget

Illuminating Safety: The Significance Of Explosion-Proof Lighting

In hazardous environments where volatile substances and flammable gases are present, ensuring safety is paramount. One crucial aspect of maintaining a secure environment is the implementation of explosion-proof lighting systems. These specialized lighting solutions are designed to prevent the ignition of hazardous substances, offering protection to both workers and facilities. This article discusses the significance of explosion-proof lighting, its major features, and the advantages it provides in hazardous environments.

Understanding Explosion-Proof Lighting

Explosion proof lighting refers to lighting fixtures that are specifically engineered to operate safely in areas where the risk of explosion or fire is high. These lighting systems are constructed with robust materials and advanced technologies to minimize the possibility of sparks or ignition in hazardous environments, such as oil refineries, chemical plants, mining sites, and industrial facilities where flammable gases, vapors, or combustible dust are present.

Key Features Of Explosion-Proof Lighting

Enclosure: Explosion-proof lighting fixtures are enclosed in a sturdy housing that can withstand extreme conditions and contain any internal explosion, preventing it from igniting the surrounding hazardous atmosphere.

Sealing: Special sealing mechanisms, such as gaskets and o-rings, are employed to create airtight seals, preventing the entry of hazardous gases or dust into the fixture. This ensures that even if an explosion occurs within the enclosure, it remains contained.

Heat Dissipation: Explosion-proof lights are designed to dissipate heat efficiently. Heat generated by the lighting components is dispersed away from the enclosure, preventing overheating and minimizing the risk of ignition.

Impact Resistance: These lighting fixtures are built to withstand harsh conditions, including impacts from machinery or accidental drops. They are constructed with rugged materials, such as corrosion-resistant metals or high-impact polycarbonate, ensuring durability in hazardous environments.

Benefits Of Explosion-Proof Lighting

Enhanced Safety: The primary advantage of explosion-proof lighting is the increased safety it provides. By minimizing the risk of ignition, these lighting systems help to prevent fires, explosions, and catastrophic accidents. They protect both workers and valuable assets in hazardous environments, reducing the potential for injuries, property damage, and downtime.

Compliance With Safety Standards: Explosion-proof lighting adheres to stringent safety requirements established by organizations such as the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA). Utilizing these approved lighting solutions ensures regulatory compliance, mitigating the risk of penalties and legal complications.

Reliable Illumination: Despite operating in hazardous environments, explosion-proof lighting fixtures deliver reliable illumination. They utilize advanced LED technology, providing bright and efficient lighting that improves visibility in work areas, enhancing productivity and reducing the risk of human errors.

Longevity And Cost-Effectiveness: Explosion-proof lighting systems are designed for longevity and require minimal maintenance. LED-based fixtures, in particular, have long lifespans, reducing the frequency of replacements. This durability leads to cost savings in terms of maintenance, replacement, and energy consumption.

Environmental Considerations: Explosion-proof LED lighting is an eco-friendly choice. LEDs consume less energy compared to traditional lighting sources, contributing to reduced carbon emissions. Moreover, they do not contain harmful substances such as mercury, making them easier to dispose of and recycle.

Versatility And Adaptability: Explosion-proof lighting is available in various configurations, including high bays, floodlights, area lights, and emergency lighting systems. This versatility allows for tailored lighting solutions that cater to specific hazardous environments, ensuring optimal illumination in every application.

Essential Types Of LED Shop Lights:

When it comes to LED shop lights, there are two essential types that are commonly used in commercial and industrial settings: high bay LED lighting and low bay LED lighting. Additionally, there are various mounting options available for these fixtures, allowing for flexibility in installation. Let’s delve into each of these types and explore the different mounting options.

High Bay Led Lighting:

High bay LED lighting fixtures are specifically designed for areas with high ceilings, typically ranging from 15 feet (4.6 meters) and above. These fixtures provide powerful illumination over large spaces, making them ideal for warehouses, manufacturing facilities, gymnasiums, and other high-ceiling environments.

Mounting Options For High Bay LED Lighting:

Chain Mount: This is the most common mounting option for high bay LED fixtures. The lights are suspended from the ceiling using chains, providing adjustable height and easy installation. Chain mounting allows for flexibility in positioning the fixtures at the desired height.

Pendant Mount: Similar to chain mounting, pendant mounting involves suspending the high bay LED fixtures from the ceiling. However, instead of chains, pendant mounts use rigid rods or pipes for support. Pendant mounts offer a sleeker and more streamlined look compared to chain mounts.

Surface Mount: In some cases, high bay LED lights can be directly mounted onto the ceiling surface. Surface mounting eliminates the need for suspending the fixtures, making it a suitable option for lower ceilings or when a more compact installation is desired.

Low Bay Led Lighting:

Low bay LED lighting fixtures are intended for places with lower ceiling heights, which generally range between 8 and 20 feet (2.4 and 6.1 meters). These fixtures provide widespread, even lighting in spaces such as retail stores, workshops, garages, and other areas with lower ceilings.

Mounting Options For Low Bay LED Lighting:

Surface Mount: Similar to high bay fixtures, low bay LED lights can be surface-mounted directly onto the ceiling. This option is convenient when there is limited ceiling height and a suspended installation is not suitable.

Suspended Mount: While less common for low bay lighting, suspended mounting is still possible in certain applications. It involves using chains or cables to hang the fixtures from the ceiling, providing adjustable height and flexibility in positioning.

Flush Mount: Flush mounting refers to installing the low bay LED fixtures directly into the ceiling, creating a seamless and integrated appearance. This mounting option is often preferred for aesthetics, especially in retail or commercial settings where a clean and unobtrusive look is desired.

Conclusion

In hazardous work environments where safety is paramount, explosion-proof lighting plays a vital role in minimizing the risk of fires and explosions. These specialized lighting solutions offer enhanced safety, regulatory compliance, and reliable illumination, while also providing cost savings and environmental benefits. By investing in explosion-proof lighting systems, industries can create safer working conditions for their employees, protect valuable assets, and ensure uninterrupted operations in hazardous settings.

-

Sports4 weeks ago

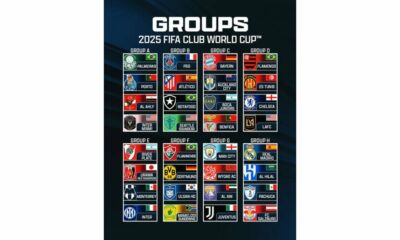

Sports4 weeks agoFIFA Club World Cup 2025: Complete List of Qualified Teams and Groups

-

Sports3 weeks ago

Sports3 weeks agoAl Ahly vs Inter Miami, 2025 FIFA Club World Cup – Preview, Prediction, Predicted Lineups and How to Watch

-

Health1 week ago

Back to Roots: Ayurveda Offers Natural Cure for Common Hair Woes

-

Tech2 weeks ago

Tech2 weeks agoFrom Soil to Silicon: The Rise of Agriculture AI and Drone Innovations in 2025

-

Sports3 weeks ago

Sports3 weeks agoFIVB Men’s Volleyball Nations League 2025: Full Schedule, Fixtures, Format, Teams, Pools and How to Watch

-

Science4 weeks ago

Science4 weeks agoEverything You Need to Know about Skywatching in June 2025: Full Moon, New Moon, Arietid Meteors, and Planetary Marvels

-

Startup3 weeks ago

Startup3 weeks agoHow Instagram Is Driving Global Social Media Marketing Trends

-

Television4 weeks ago

Television4 weeks agoTribeca Festival 2025: Date, Time, Lineups, Performances, Tickets and How to Watch