Business

Ford closing down Chicago Assembly Plant one week from now, briefly laying off laborers

Ford plans to incidentally close down the Chicago Assembly Plant and lay off laborers one week from now because of the global semiconductor shortage that is significantly upset the automotive industry.

The automotive plant on the banks of the Calumet River on Chicago’s far South Side, directly across the state line, will be covered for the week alongside Ford’s Flat Rock Assembly Plant, Dearborn Truck Plant and Louisville Assembly Plant.

Ford likewise plans to close down the transit side of the Kansas City Assembly Plant and work the Ohio Assembly Plant at a decreased level due to parts deficits.

The closure will influence a huge number of automotive jobs at the Chicago Assembly Plant in Hegewisch, the Chicago Stamping Plant in Chicago Heights, and at providers all through the Region like Lear Corp. in Hammond, UGN in Valparaiso and Flex-N-Gate on the South Side.

Lear, for example, makes seats for the Ford Explorer, Lincoln Aviator and Police Interceptor Utility that are produced at the Chicago Assembly Plant. They are conveyed without any inventories developed so the provider’s tasks are synchronized with Ford’s.

“The global shortage is affecting all automotive manufacturers as well as other industries,” Ford Vice President of Manufacturing and Labor Affairs John Savona wrote in a letter to workers. “Our MP&L, purchasing and manufacturing teams have been working tirelessly to find solutions to keep our plants running so you can continue building high-quality vehicles that continue to be in high demand among our dealers and customers. One of those solutions is sequencing down weeks, allowing us to keep building our must-have vehicles for customers when we have adequate parts suppliers.”

The global semiconductor shortage was brought about by Covid pandemic-related interruptions and catastrophic events. It’s especially critical for automakers since vehicles depend more on PCs as they become all the more technologically advanced, for example, with lane-assist and collision-avoidance systems.

Ford previously needed to decrease tasks to one move for seven days at the Chicago Assembly Plant recently. The Alliance for Automotive Innovation appraises the auto industry in America could end up developing 1 million less vehicles this year because of the parts deficiencies.

Dearborn-based Ford is canceling the traditional summer closures when support is done at the plants and laborers take some time off on account of the production disturbances.

“We understand these schedule disruptions are inconvenient,” Savona wrote in the letter to workers. “We also appreciate that this year’s summer schedule may be disappointing to those who look forward to time away during the traditional shutdown weeks. We thank you for your flexibility, understanding and your dedication — as we’ve seen throughout COVID-19 challenges and this year’s semiconductor shortages. We will get through this, working together, and we appreciate all you do for Ford every day.”

The United Auto Workers association urged its individuals to petition for unemployment insurance benefits while the plant was sat one week from now.

Ford employs 5,810 workers at the Chicago Assembly Plant and 1,290 at the Chicago Stamping Plant. Thousands more work at Tier 1 providers like the Lear factory in Hammond only south of the East Chicago South Shore Line train station.

-

Sports4 weeks ago

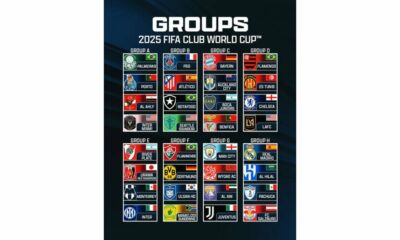

Sports4 weeks agoFIFA Club World Cup 2025: Complete List of Qualified Teams and Groups

-

Sports3 weeks ago

Sports3 weeks agoAl Ahly vs Inter Miami, 2025 FIFA Club World Cup – Preview, Prediction, Predicted Lineups and How to Watch

-

Health2 weeks ago

Back to Roots: Ayurveda Offers Natural Cure for Common Hair Woes

-

Tech2 weeks ago

Tech2 weeks agoFrom Soil to Silicon: The Rise of Agriculture AI and Drone Innovations in 2025

-

Sports3 weeks ago

Sports3 weeks agoFIVB Men’s Volleyball Nations League 2025: Full Schedule, Fixtures, Format, Teams, Pools and How to Watch

-

Startup3 weeks ago

Startup3 weeks agoHow Instagram Is Driving Global Social Media Marketing Trends

-

Television4 weeks ago

Television4 weeks agoTribeca Festival 2025: Date, Time, Lineups, Performances, Tickets and How to Watch

-

Sports3 weeks ago

Sports3 weeks agoWorld Judo Championships 2025: Full Schedule, Date, Time, Key Athletes and How to Watch