Business

Tesla’s next plant will be built in Mexico

Elon Musk, Tesla’s CEO, announced on Wednesday that the company’s next vehicle assembly plant will be in Mexico near Monterrey.

During the company’s investor day, Musk stated, “We’re super excited about it. We’ll continue to expand production at all of our existing factories. So this is not moving output to anywhere, from anywhere. This is supplemental production.”

In Fremont, California, the company currently has four factories with the capacity to produce approximately 2 million automobiles annually; China’s Shanghai; Texas’ Austin; and Germany’s Berlin. In the end, it wants to produce 20 million cars per year. In 2022, the business delivered just over 1.3 million vehicles. In 2022, Toyota, the world’s largest automaker by volume, sold just over 10 million vehicles around the world.

The new plant’s cost was not discussed by Tesla. The announcement was a confirmation of the plans that Mexican President Andres Manuel Lopez Obrador made on Tuesday to have Tesla construct its next factory in the country. Mexican officials said the plant could cost $1 billion.

The company anticipates spending $150 billion to $175 billion to construct the additional plants required to produce 20 million vehicles, including the $28 billion investment it has already made throughout its history.

“Maybe this total investment looks large,” said CFO Zachary Kirkhorn. “I think it’s quite a small relative to our ambitions.”

Additionally, the company announced earlier this week that it has produced 4 million vehicles in its history.

Even though Tesla (TSLA) shares fell more than 5% in after-hours trading on Wednesday, this was a slight improvement from the larger decline that occurred before Musk’s announcement, which occurred more than three hours into the presentation. Some investors had hoped that Tesla (TSLA) would reveal specifics about a new vehicle generation. Musk declined to respond to a question regarding the forthcoming automobile.

“We will have a proper sort of product event,” Musk said. “We’d be jumping the gun if we were to answer that question.”

In response to a second inquiry from an analyst, Musk stated that he does not anticipate Tesla ever offering more than ten distinct vehicle models. He criticized the competing automakers’ extensive offerings as nothing more than a “shuffling” of numerous models that were very similar.

Tax credits of up to $7,500 were reinstated for buyers of Tesla’s less expensive Model 3 and Model Y vehicles last year by the Inflation Reduction Act, provided that the vehicles’ list prices were less than $55,000. The cars must be assembled in North America to be eligible for the tax credit, so the final product from the Mexico plant should be eligible.

Mexico already houses assembly facilities for the majority of global automakers. There are 20 auto assembly plants in the country. General Motors has three, while Ford has two, one of which produces the Mustang Mach-E, an electric SUV that competes with Tesla. There are three at Stellantis, which produces automobiles under the Chrysler, Dodge, Ram, and Jeep brands.

Additionally, Mexico is home to manufacturing facilities for BMW, Toyota, Honda, Nissan, Volkswagen, Audi, Mazda, Mercedes, and Kia.

Before the pandemic reduced the supply of auto parts, particularly computer chips, and auto production worldwide, Mexican plants were producing just under 4 million cars per year, according to statistics from the US Trade Administration, a division of the Commerce Department. Last year, they produced approximately 3.5 million cars. As a result, it ranks seventh in terms of automobile production.

However, it exports 90% of its cars, with 76% going to the United States.

-

Sports4 weeks ago

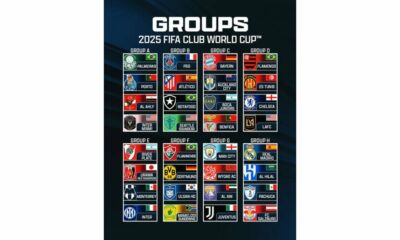

Sports4 weeks agoFIFA Club World Cup 2025: Complete List of Qualified Teams and Groups

-

Sports3 weeks ago

Sports3 weeks agoAl Ahly vs Inter Miami, 2025 FIFA Club World Cup – Preview, Prediction, Predicted Lineups and How to Watch

-

Health2 weeks ago

Back to Roots: Ayurveda Offers Natural Cure for Common Hair Woes

-

Tech2 weeks ago

Tech2 weeks agoFrom Soil to Silicon: The Rise of Agriculture AI and Drone Innovations in 2025

-

Sports4 weeks ago

Sports4 weeks agoFIVB Men’s Volleyball Nations League 2025: Full Schedule, Fixtures, Format, Teams, Pools and How to Watch

-

Startup3 weeks ago

Startup3 weeks agoHow Instagram Is Driving Global Social Media Marketing Trends

-

Sports3 weeks ago

Sports3 weeks agoWorld Judo Championships 2025: Full Schedule, Date, Time, Key Athletes and How to Watch

-

Sports2 weeks ago

Sports2 weeks agoFIBA 3×3 World Cup 2025: Full Schedule, Preview, and How to Watch