Business

Tesla stops most production at the Shanghai plant because of parts supply issues

Tesla has stopped the vast majority of its production at its Shanghai plant because of issues getting parts for its electric vehicles (EVs), as per an internal memo, the latest in a series of troubles for the factory.

The suspension comes only three weeks after the US automaker somewhat continued production at the Shanghai plant on Apr 19 following a 22-day closure brought about by the city’s COVID-19 lockdown, reflecting the complexity and vulnerabilities of moving to assemble along as China fights the Covid.

Tesla diminished vehicle production at its Shanghai manufacturing plant this week because of parts deficiencies caused to some extent by a provider’s Covid lockdown.

Production at Tesla’s Shanghai plant floundered after city officials once again introduced severe COVID-19 lockdown measures in March, compelling Tesla to close its plant to agree with government orders. Tesla’s Shanghai factory reopened in April, with laborers resting and eating inside the processing plant in a “closed-loop system” prescribed by Shanghai authorities to stop the spread of COVID-19.

The plant intends to make less than 200 vehicles on Tuesday (May 10), as indicated by the update, definitely not exactly the around 1,200 units it has been constructing every day since soon after it reopened on April 19 following a 22-day closure.

Two sources acquainted with the matter had before said supply issues had constrained the factory to stop production on Monday.

Shanghai is in its 6th week of a strengthening Covid-19 lockdown that has tested the ability of makers to work amid hard limitations on the movement of people and materials.

Tesla had planned as late as last week to expand output to pre-lockdown levels by the next week.

It was not quickly clear when the current supply issues could be resolved, said, individuals.

It is unclear when the supply issues can be resolved and when Tesla can continue production, said individuals, who declined to be recognized as the matter is private. Shanghai is presently in its 6th week of lockdown.

Among Tesla providers confronting issues is wire harness producer Aptiv which needed to prevent shipping supplies from a plant that provisions Tesla and General Motors after diseases were found among its workers, sources said on Monday.

Tesla didn’t immediately respond to a request for comment.

The organization was planning to increment output at its Shanghai plant to 2,600 cars per day from May 16 as it looks to re-establish production to levels before the lockdown.

The disturbance to Tesla’s Shanghai plant has been one of the highest profile results of China’s measures to control its greatest COVID-19 flare-up, which has additionally creased consumption, including vehicle sales.

The China Passenger Car Association is planning to release April sales for Tesla, China’s second-biggest EV creator behind BYD, on Tuesday.

Another auto association said last week it assessed that overall auto sales in China dropped 48% in April as zero-Covid-19 lockdowns shut manufacturing plants, restricted traffic to showrooms, and put the brakes on spending.

Aptiv, Tesla’s main supplier of wire harnesses, prevented transporting from a Shanghai plant that provisions Tesla and General Motors after Covid-19 diseases were found among its laborers, two individuals acquainted with the matter told on Monday.

Tesla’s Shanghai plant, otherwise called the Gigafactory 3, produces the Model 3 sedan and Model Y crossover for the China market and export.

Tesla to some extent continued production at the Shanghai plant on April 19 and had been intending to increment output at its Shanghai plant to 2,600 vehicles per day from May 16.

The Shanghai specialists have tightened a citywide lockdown forced over a month prior on the commercial hub with a population of 25 million, a move that could expand controls on development as the month progressed.

As indicated by JL Warren Capital CEO and Director of Research Junheng Li, a Covid case recognized at an Aptiv production line in the Jiading district of Shanghai led specialists to close that facility temporarily. Aptiv makes a cable harness used in Tesla’s battery electric crossover, the Model Y, at that plant.

Tesla then, at that point, temporarily shut down some of its production lines for Model Y at its Shanghai Gigafactory, JL Warren scientists affirmed.

Last week, Chinese President Xi Jinping held a meeting with top leaders of the country where he accentuated that China ought to adhere to its “dynamic zero-Covid” policy. He called on the country to mobilize behind central committee decisions of the Chinese Communist Party and “resolutely fight” against all questioning of virus control policies.

JL Warren’s Li said, “This statement set the mandate for all local authorities to prioritize zero-Covid over regional economies. So automakers are planning day by day, week by week.” Her firm expects parts shortages, supply chain issues, and production shutdowns to be recurring into the foreseeable future. JL Warren Capital specializes in market research on organizations operating in China, with more than 200 consultants on the ground there.

Coronavirus lockdowns emphatically influenced Tesla’s production in China last month, also.

As indicated by China Passenger Car Association numbers out Tuesday, Tesla sold 1,512 China-made electric vehicles in the country in April, a drop of over 95% from the prior month. It created an expected 10,757 electric vehicles at its Shanghai plant in April, yet didn’t export any to Europe or points in Asia beyond mainland China as it had done in earlier months.

In the first four months of 2022, Tesla sold 183,686 of its China-made electric vehicles, CPCA estimates, 73,874 of which are sent out of the country.

On Tuesday, Tesla CEO Elon Musk said during an interview with the Financial Times, “I’ve had some conversations with the Chinese government in recent days, and it’s clear that the lockdowns are being lifted rapidly, so I would not expect this to be a significant issue in the coming weeks.”

During a first-quarter earnings call last month Tesla CFO Zachary Kirkhorn said, “We’ve lost about a month of build volume out of our factory in Shanghai due to Covid-related shutdowns. Production is resuming at limited levels, and we’re working to get back to full production as quickly as possible. This will impact total build and delivery volume in Q2.”

Aptiv and Tesla didn’t respond to requests for comment on the CPCA numbers or China production issues.

Information from the China Passenger Car Association (CPCA) shows that Tesla’s sales in China have slid by 98% in April, with Tesla selling producing 10,757 vehicles and selling only 1,512. Tesla constructed 55,462 vehicles at its Shanghai factory in March and sold 65,814.

Last quarter, Tesla sold a record 310,000 vehicles regardless of Tesla CEO Elon Musk considering it an “exceptionally difficult quarter” because of terminations at its Shanghai plant toward the finish of March and global supply chain issues.

-

Sports4 weeks ago

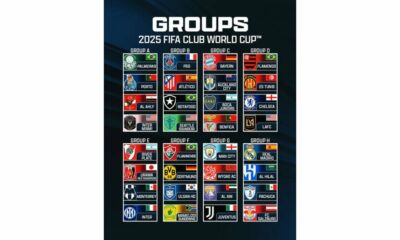

Sports4 weeks agoFIFA Club World Cup 2025: Complete List of Qualified Teams and Groups

-

Sports3 weeks ago

Sports3 weeks agoAl Ahly vs Inter Miami, 2025 FIFA Club World Cup – Preview, Prediction, Predicted Lineups and How to Watch

-

Health2 weeks ago

Back to Roots: Ayurveda Offers Natural Cure for Common Hair Woes

-

Tech2 weeks ago

Tech2 weeks agoFrom Soil to Silicon: The Rise of Agriculture AI and Drone Innovations in 2025

-

Sports4 weeks ago

Sports4 weeks agoFIVB Men’s Volleyball Nations League 2025: Full Schedule, Fixtures, Format, Teams, Pools and How to Watch

-

Startup3 weeks ago

Startup3 weeks agoHow Instagram Is Driving Global Social Media Marketing Trends

-

Sports3 weeks ago

Sports3 weeks agoWorld Judo Championships 2025: Full Schedule, Date, Time, Key Athletes and How to Watch

-

Sports2 weeks ago

Sports2 weeks agoFIBA 3×3 World Cup 2025: Full Schedule, Preview, and How to Watch