Business

Toyota will sever car production by 40% over global chip shortage

Toyota says it will cut global production for September by 40% from its past plan, becoming the last significant automaker to slice output because of a global chip crunch, yet it kept up with its annual sales and production targets.

Toyota’s accomplishment in exploring the chip shortage better than rivals has descended to its bigger store of chips under a business coherence plan embraced after the 2011 earthquake and the Fukushima nuclear disaster.

The world’s biggest automaker by sales volumes reiterated its global production target of 9.3 million vehicles for the year finishing off with March, as well as its plan to sell 8.7 million vehicles in the period.

“The 9.3 million global production plan takes into account certain risks,” executive Kazunari Kumakura told columnists.

“We want to achieve the numbers.”

Toyota said the September cuts included 14 factories for Japan and overseas plants, and that the organization would diminish its planned global production that month by around 360,000 vehicles.

Of these, 140,000 will be at Japanese plants, with the rest in the United States, China, Europe, and other Asian nations.

Carmakers worldwide have been cutting production because of the months-long chip lack, yet a resurgence in COVID-19 cases in Japan, the Philippines, Thailand, Vietnam, and Malaysia — home to auto production lines and chip plants — have prompted stricter curbs and intensified the emergency.

Germany’s Volkswagen said it likewise may have to cut production further and that it expected the supply of chips in the third quarter to be “very volatile and tight”.

Ford Motors said would briefly close its Kansas City assembly plant that forms its best-selling F-150 pickup truck because of a semiconductor-related part deficiency because of rising cases in Malaysia.

Recently, Toyota had flagged an unpredictable business environment due to new COVID-19 cases in arising economies, the semiconductor shortage, and taking off material costs.

Toyota shares shut down 4.4 percent in their biggest daily drop since December 2018, pulling the benchmark Nikkei average to a seven-month low.

The carmaker had already ended assembly lines at some Japanese factories between late July and early August, including its Tahara plant, because of a surge in infections in Vietnam which had compelled the supply of parts, the Nikkei revealed prior.

An individual acquainted with the matter revealed to Reuters this month that Toyota had additionally suspended production at one assembly line in Guangzhou, China, which it works with its Chinese joint-venture partner Guangzhou Automobile Group.

In Thailand as well, Toyota suspended production last month at three factories because of a pandemic-related parts shortage.

-

Sports4 weeks ago

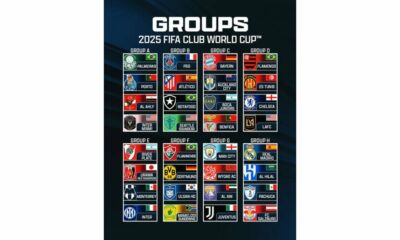

Sports4 weeks agoFIFA Club World Cup 2025: Complete List of Qualified Teams and Groups

-

Sports3 weeks ago

Sports3 weeks agoAl Ahly vs Inter Miami, 2025 FIFA Club World Cup – Preview, Prediction, Predicted Lineups and How to Watch

-

Health2 weeks ago

Back to Roots: Ayurveda Offers Natural Cure for Common Hair Woes

-

Tech2 weeks ago

Tech2 weeks agoFrom Soil to Silicon: The Rise of Agriculture AI and Drone Innovations in 2025

-

Sports4 weeks ago

Sports4 weeks agoFIVB Men’s Volleyball Nations League 2025: Full Schedule, Fixtures, Format, Teams, Pools and How to Watch

-

Startup3 weeks ago

Startup3 weeks agoHow Instagram Is Driving Global Social Media Marketing Trends

-

Sports3 weeks ago

Sports3 weeks agoWorld Judo Championships 2025: Full Schedule, Date, Time, Key Athletes and How to Watch

-

Sports2 weeks ago

Sports2 weeks agoFIBA 3×3 World Cup 2025: Full Schedule, Preview, and How to Watch