Tech

Ways in Which the Cutting-Edge Laser Marking Technology Could Benefit Your Business

Laser marking has become standard practice in a number of industries, including the production of electronic goods, medical devices, and automobiles. In response to the need for faster, more precise, and better marked objects, laser marking technologies have emerged. Recent and promising developments in the field will be discussed.

The saving power of fiber lasers!

Fiber lasers completely change the laser marking industry, as their speed and accuracy is far beyond those of conventional CO2 lasers. More precise markings are possible because of fiber-optic connections that direct the laser beam with pinpoint accuracy. Fiber lasers have a lower total cost of ownership than CO2 lasers because they last longer and require less upkeep. They use less power, lowering laser marking’s environmental impact.

Accelerating Lasers

With the advent of ultrafast lasers, hitherto inaccessible surfaces are now capable of bearing high-quality, detailed markings. These lasers can have their marking energy precisely controlled because their pulses last only for a fraction of a second (femtosecond or picosecond). Marking glass, ceramics, and even some polymers is now possible with ultrafast lasers. Since they produce so little heat, they can be used to label even sensitive materials.

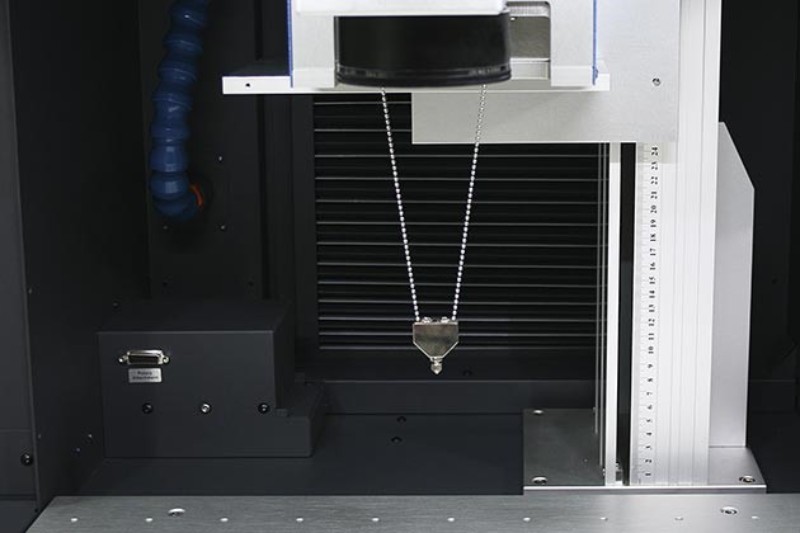

Using a Laser Rangefinder in Three Dimensions

Due to the fact that conventional laser marking techniques necessitate a flat surface for the marking process, only a select few products are suitable for laser marking. Before the advent of 3D laser marking technology, manufacturers had a hard time correctly recognizing objects with complex or irregular shapes. This precision is made possible by 3D laser marking, which builds a 3D model of the target using specialist software. The laser beam may be controlled to follow the contours of the object, allowing for exact inscriptions on even the hardest materials.

Marking using a Color Laser

Color laser marking has made it possible to leave high-quality, long-lasting color marks on many different types of materials. By combining different laser wavelengths, this technology can produce any color from white to black and every shade in between. In industries where color labeling is required, such as medical device production or electronics assembly, color laser marking can be an invaluable tool. The potential for more artistic and aesthetically pleasing product branding expands, allowing for new avenues of exploration in product design and marketing.

Using a laser for marking is a cinch.

The most recent development is smart laser marking, which uses AI and machine learning to automate formerly labor-intensive marking processes. For the most precise markings, smart laser marking systems collect data from sensors and cameras embedded in or nearby the target item. As a result of this technological development, the marking process is improved because less trash is produced and fewer people are needed to complete the process. In addition to simplifying the marking process, smart laser marking also gathers and analyzes data that may be utilized for quality assurance and enhancement of the product.

Conclusion

Improvements in laser marking technology have ushered in a new era of productivity, accuracy, and adaptability in the marking business. Some examples of technologies that have provided new opportunities for product design and manufacturing are fiber lasers, 3D laser marking, and smart laser marking. There will likely be many more fascinating breakthroughs in laser marking as time goes on. The increasing need for dependable, eco-friendly product labels necessitates cutting-edge production techniques from companies who wish to meet consumer demand. Therefore, it is appropriate for the players in this industry to be pro-actively informed on the developments in this area to make sure they remain competitive in the industry.

-

Sports4 weeks ago

Sports4 weeks agoAl Ahly vs Inter Miami, 2025 FIFA Club World Cup – Preview, Prediction, Predicted Lineups and How to Watch

-

Health3 weeks ago

Back to Roots: Ayurveda Offers Natural Cure for Common Hair Woes

-

Tech3 weeks ago

Tech3 weeks agoFrom Soil to Silicon: The Rise of Agriculture AI and Drone Innovations in 2025

-

Startup4 weeks ago

Startup4 weeks agoHow Instagram Is Driving Global Social Media Marketing Trends

-

Sports3 weeks ago

Sports3 weeks agoFIBA 3×3 World Cup 2025: Full Schedule, Preview, and How to Watch

-

Science4 days ago

Science4 days agoJuly Full Moon 2025: Everything You Should Need to Know, When and Where to See Buck Moon

-

Gadget3 weeks ago

Gadget3 weeks agoThings to Know about Samsung Galaxy S26: What’s New and What’s Next

-

Sports4 weeks ago

Sports4 weeks agoWorld Judo Championships 2025: Full Schedule, Date, Time, Key Athletes and How to Watch